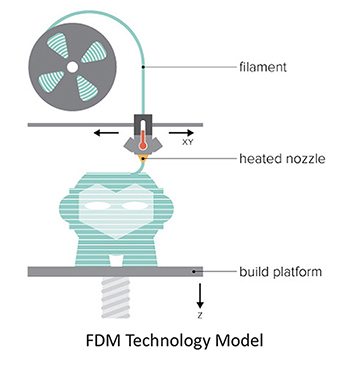

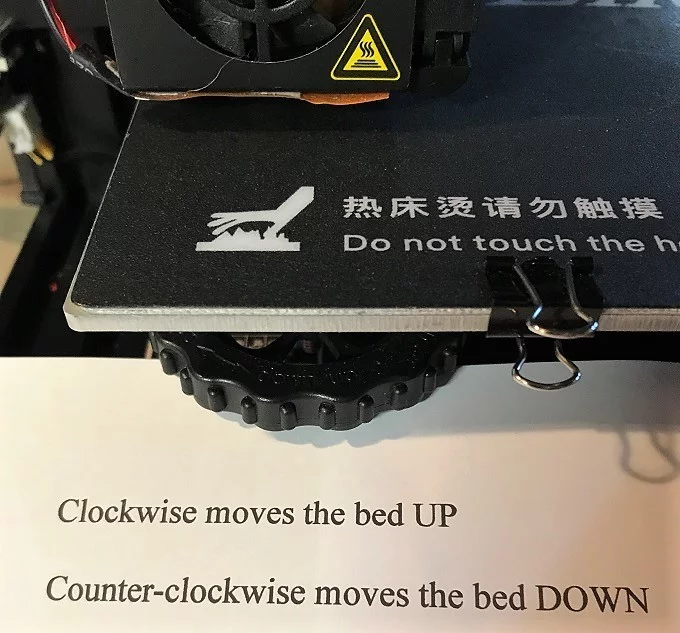

3d printing is similar to printing on paper, the nozzle of the printer moves back and forth making a shape. However what makes 3d

printing different to regular printing is that it prints with plastic not ink and that there is an extra axis, the z axis, which moves the nozzle up.

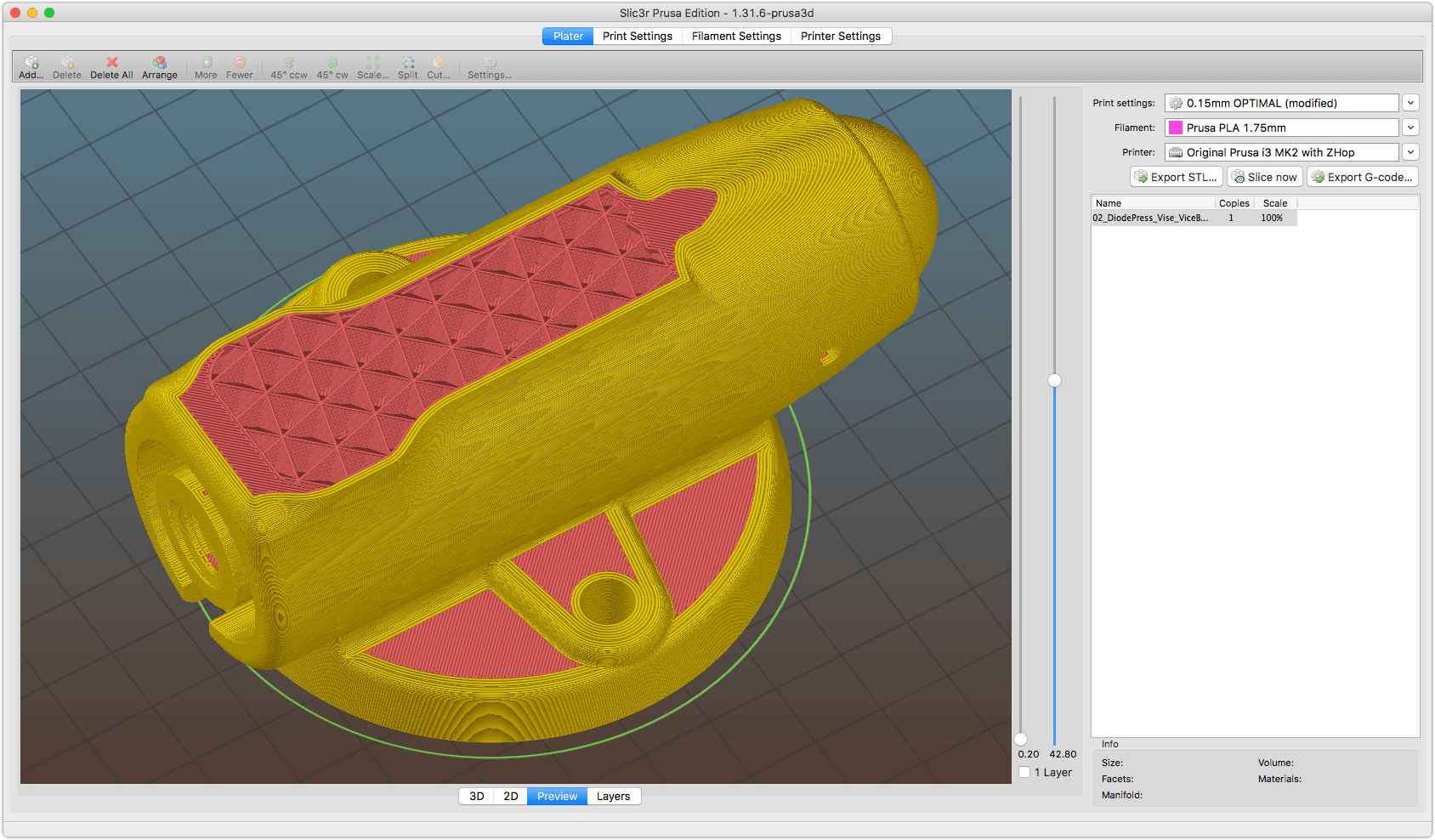

so instead of only printing one shape a 3d printer prints many shapes on top of each other, in layers, forming a 3d model.

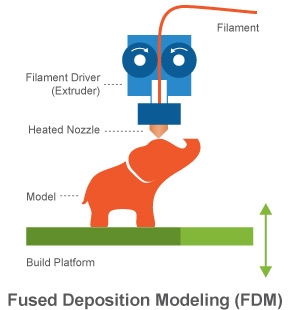

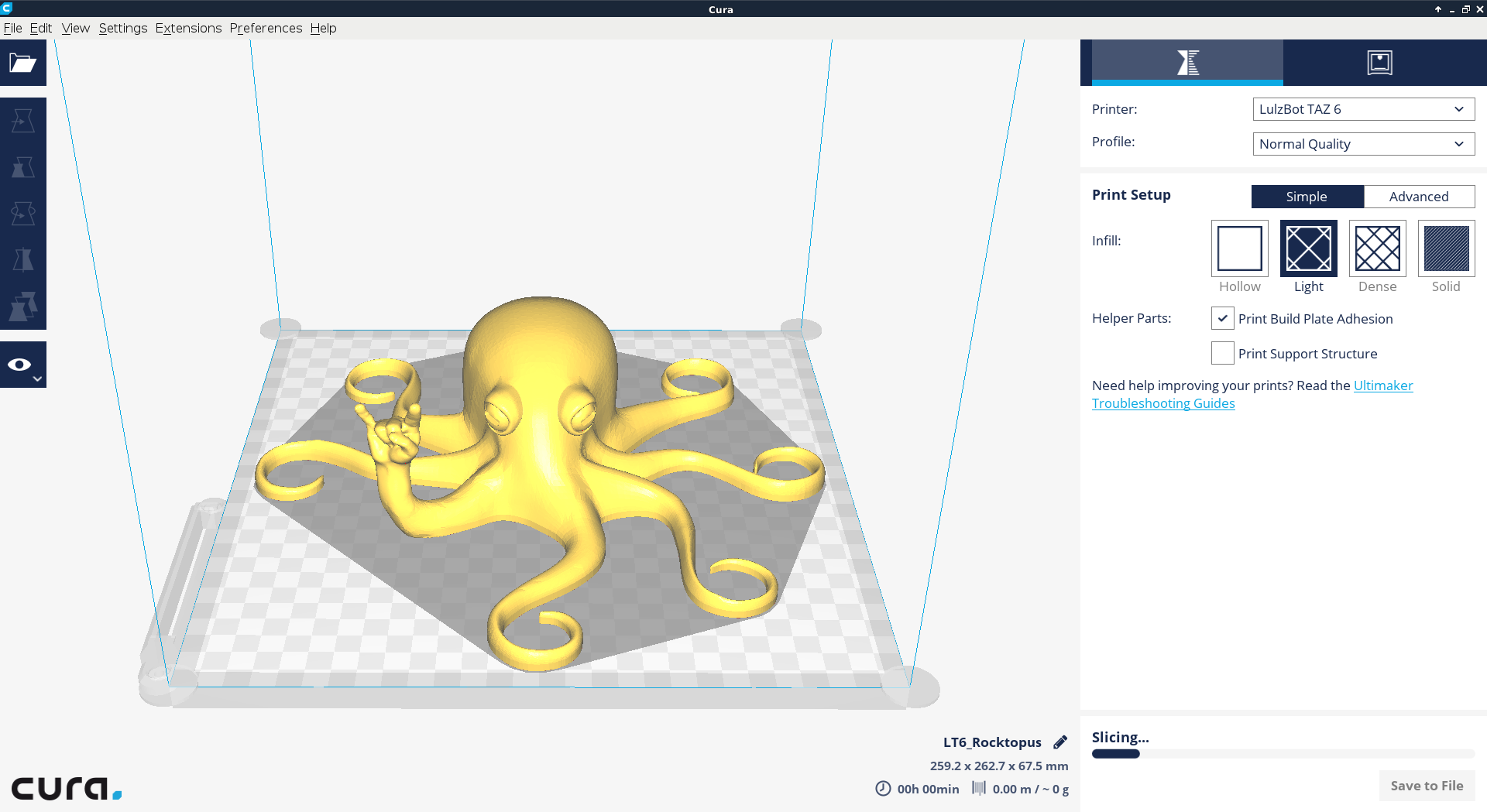

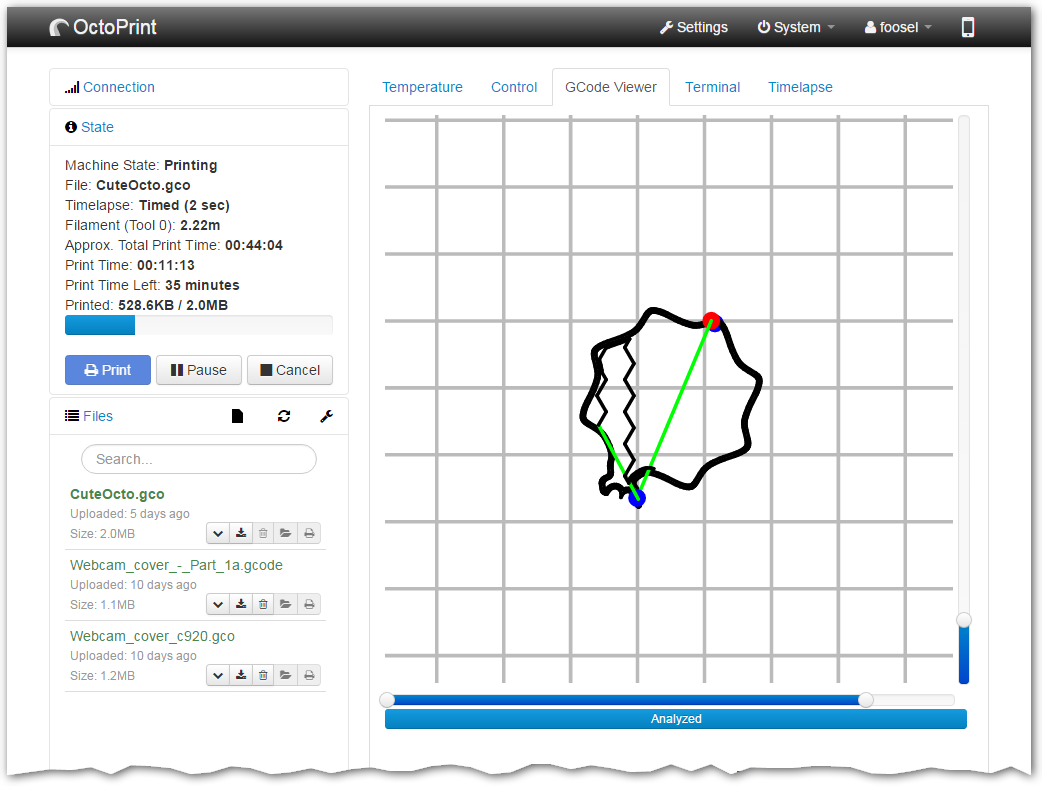

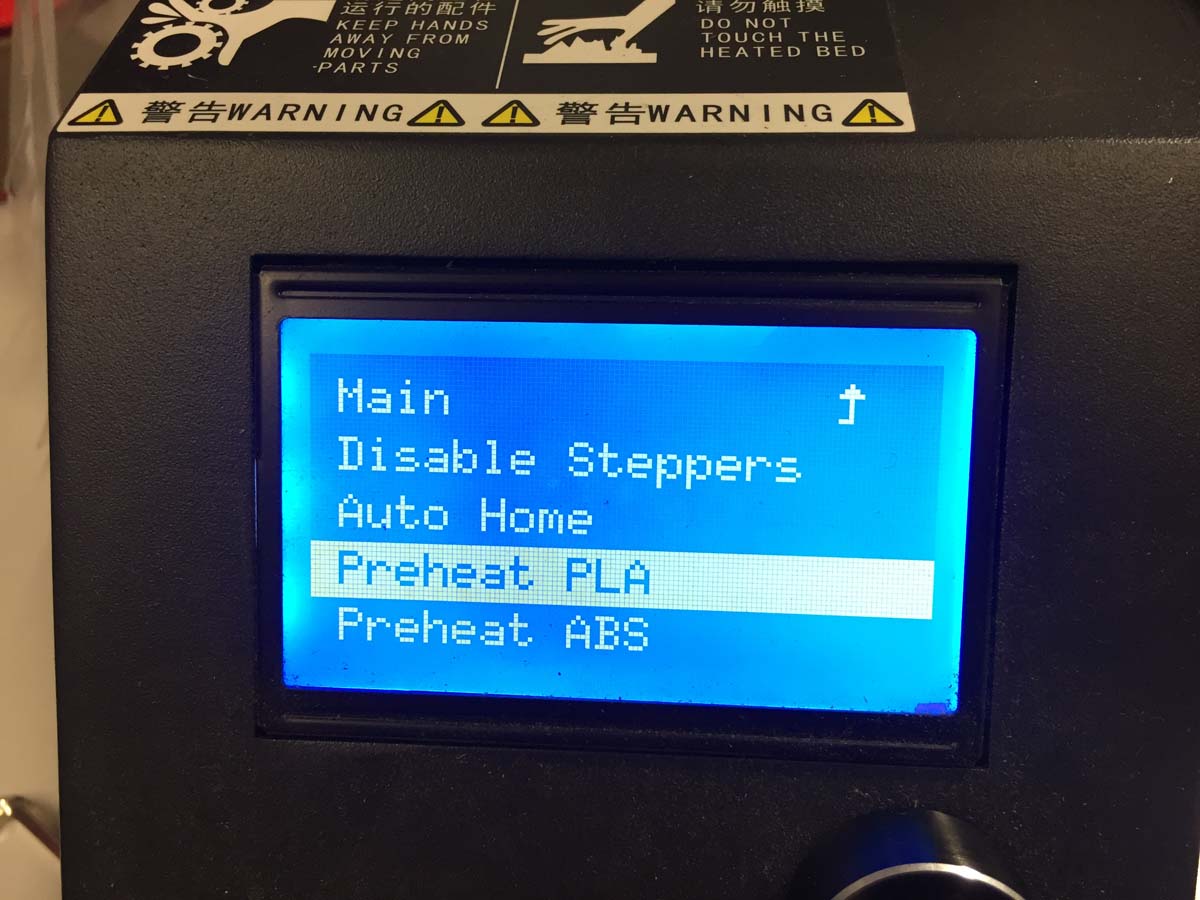

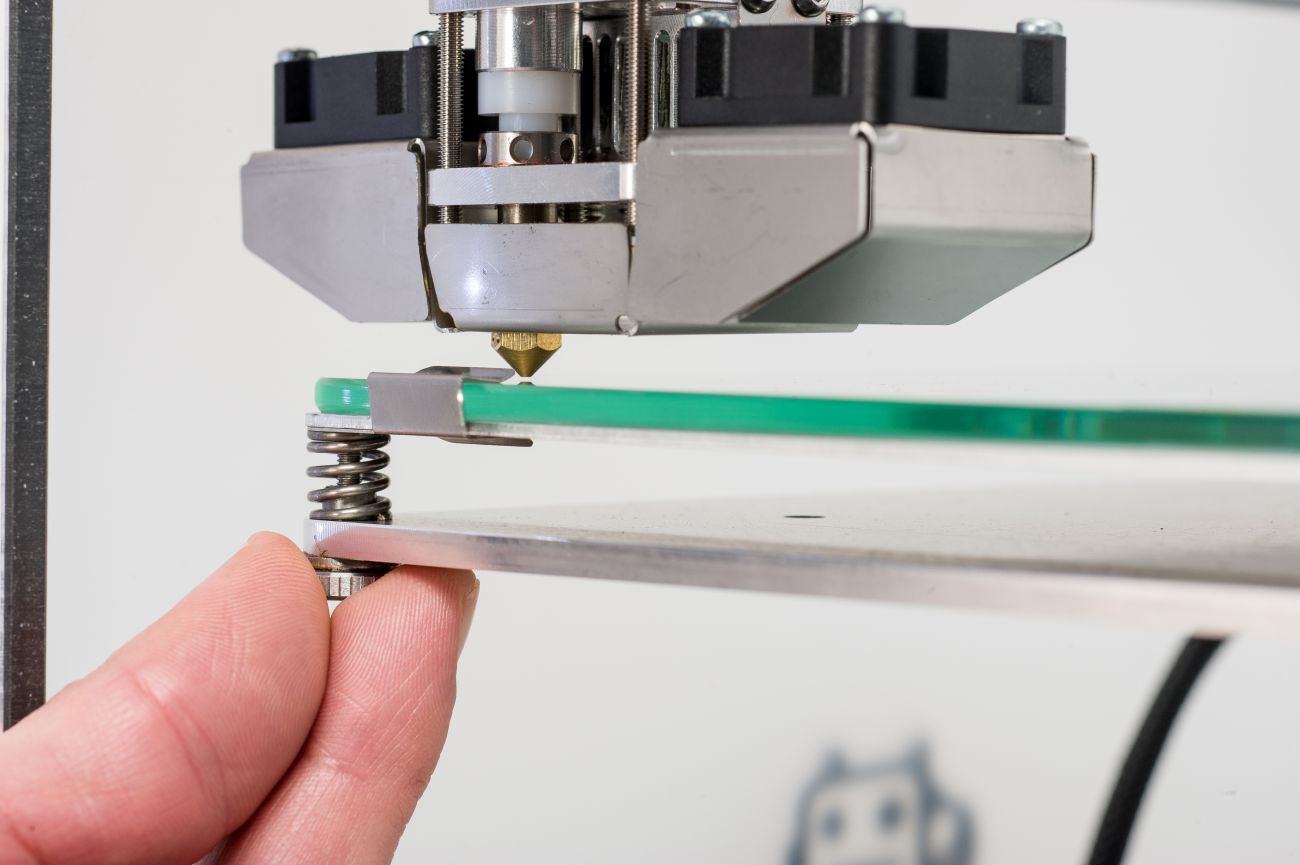

The most common form of 3d printing is FDM (Fused Deposition Modelling) printing, which is shown in the diagrams to the left. To put

it simply FDM printing is when layers of molten plastic are printed on top of each other, each fusing to the layer beneath it.